Daily maintenance methods of glass drilling machine

- Categories:News

- Author:

- Origin:

- Time of issue:2021-01-19 18:30

- Views:

(Summary description)What are the daily maintenance methods of glass drilling machine in use?

Daily maintenance methods of glass drilling machine

(Summary description)What are the daily maintenance methods of glass drilling machine in use?

- Categories:News

- Author:

- Origin:

- Time of issue:2021-01-19 18:30

- Views:

What are the daily maintenance methods of glass drilling machine in use?

1.Oil pump maintenance

Check the oil pump quantity of drilling machine every day, and keep the lubricating oil level of automatic oil pump not lower than safe level. If it is lower than the safe oil level, the system will give an alarm message to remind the user to add lubricating oil.

2.Drill bit maintenance

Pay attention to the wear of drill bit at any time. If it is found that the bit needs to be replaced, the bit on the machine should be replaced and the feed compensation should be made in time to avoid the influence on the accuracy of the glass due to excessive wear of the bit.

3.Maintenance of screw/ guide rail / oil circuit

X / Y axis: disassemble the X / Y axis stainless steel waterproof cover every week to check whether the linear guide rail, ball screw and oil circuit are in place. At the same time, open the oil pump to observe whether the lubricating oil can be in place and whether the oil pipe is blocked or broken! Install the stainless steel waterproof cover. Move the XY axis back and forth to the maximum stroke every day to ensure that all parts are lubricated in place within the effective stroke.

Up and down drilling: dismantle the stainless steel waterproof cover of up and down drilling every week, and check whether the linear guide rail, ball screw and oil circuit are in place. At the same time, open the oil pump to observe whether the lubricating oil can be in place and whether the oil pipe is blocked or broken! Install the stainless steel waterproof cover. During daily lubrication, move up and down to the maximum stroke to ensure that all parts are lubricated in place within the effective stroke.

Before operating the machine every day, first click the oil pump on the console to refuel. The refueling time and interval can be set according to your own frequency;

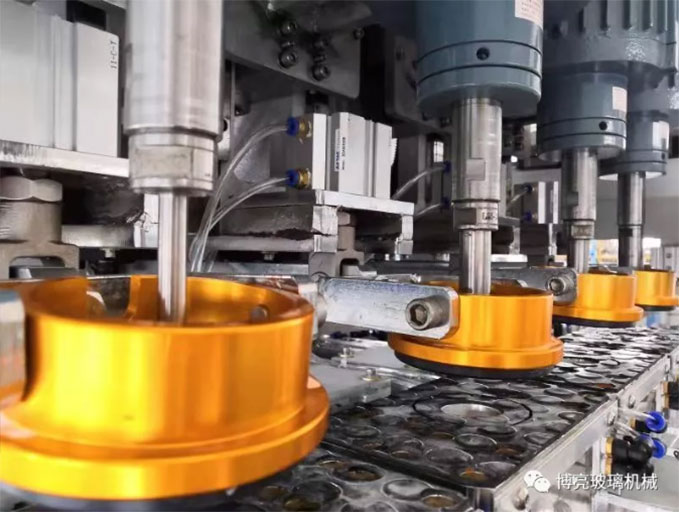

4.Maintenance of water swivel

Check whether the water connection rotary joint of vulnerable parts has water leakage every day. If there is water leakage, it should be replaced in time. It can be observed through the observation window (as shown in the figure). It is strictly forbidden for foreign matters to enter the inside of the water connection rotary joint to cause abnormal wear, and the rotary joint shall not idle for a long time. Keep the inside of rotary joint cylinder and pipe clean.

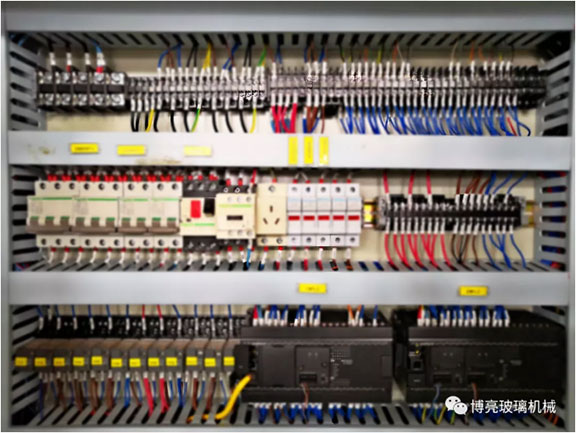

5.Maintenance of electric cabinet

Check the electric cabinet every day, cleaning and dusting, and keep the inside of the electric cabinet clean and tidy. Check the working condition of the fan of the electric cabinet, and keep the electric cabinet fully cooled and ventilated.

6.Daily inspection before operation

First: according to the production situation, clean the slag plate of machine glass slag irregularly. Avoid excessive glass debris accumulation after the drilling machine is completed, which will affect the normal operation of the machine.

Second: pay attention to safety when debugging and using the machine. Do not touch the moving parts and live parts when starting the machine.

Third: check whether all travel switches work normally and whether the control direction is correct before operation. If it is not correct and the control direction is not right, stop the machine immediately for inspection, otherwise the machine will be fatally damaged.

Fourth: tools and other objects should not be placed on the machine's transport guide rail and body surface, which may affect the operation of the machine and cause accidents.

Fifthly, before starting the glass drilling machine which has not been used for a long time, the moving parts of the machine should be cleaned, and the lubricating oil should be added to the oil filling parts.

Sixth: in case of emergency, immediately take down the emergency stop switch or turn off the main power switch of the equipment.

The above is part of the maintenance methods of BLM CNC drilling machine.

In order to better protect the safety of personnel and property,

please keep in mind the above precautions and follow the equipment instructions.

Scan the QR code to read on your phone

Guangdong BLM Machinery Co.,Ltd. (Foshan Boliang Glass Machinery Co.,Ltd) was established in 2007 as a glass deep processing machinery manufacturer integrated with R&D, production, sales and after-sales service.

ADD:NO.8,Phoenix Road, National Ecological Industry Demonstration Park, Danzao Town, Nanhai District FoshanCity,Guangdong Province .P.R.C

TEL:0757-81797808

EMAIL:sales@boliangjx.com

All rights reserved © 2020 Guangdong BLM Machinery Co.,Ltd ICP:2021006844号 WEBSITE:XINNET